Revolutionizing Textile Design with AI-Powered Visualization at Toyoshima

Toyoshima Inc.

Visit Website

70% waste reduction

50% faster design

30% Market Expansion

Toyoshima, a leader in the textile industry, faced significant challenges with its traditional fabric design and visualization processes. Physical sample creation extended product development cycles to months or even years, limiting creativity and market responsiveness. With a high-profile global exhibition approaching in July, Toyoshima needed a transformative solution.

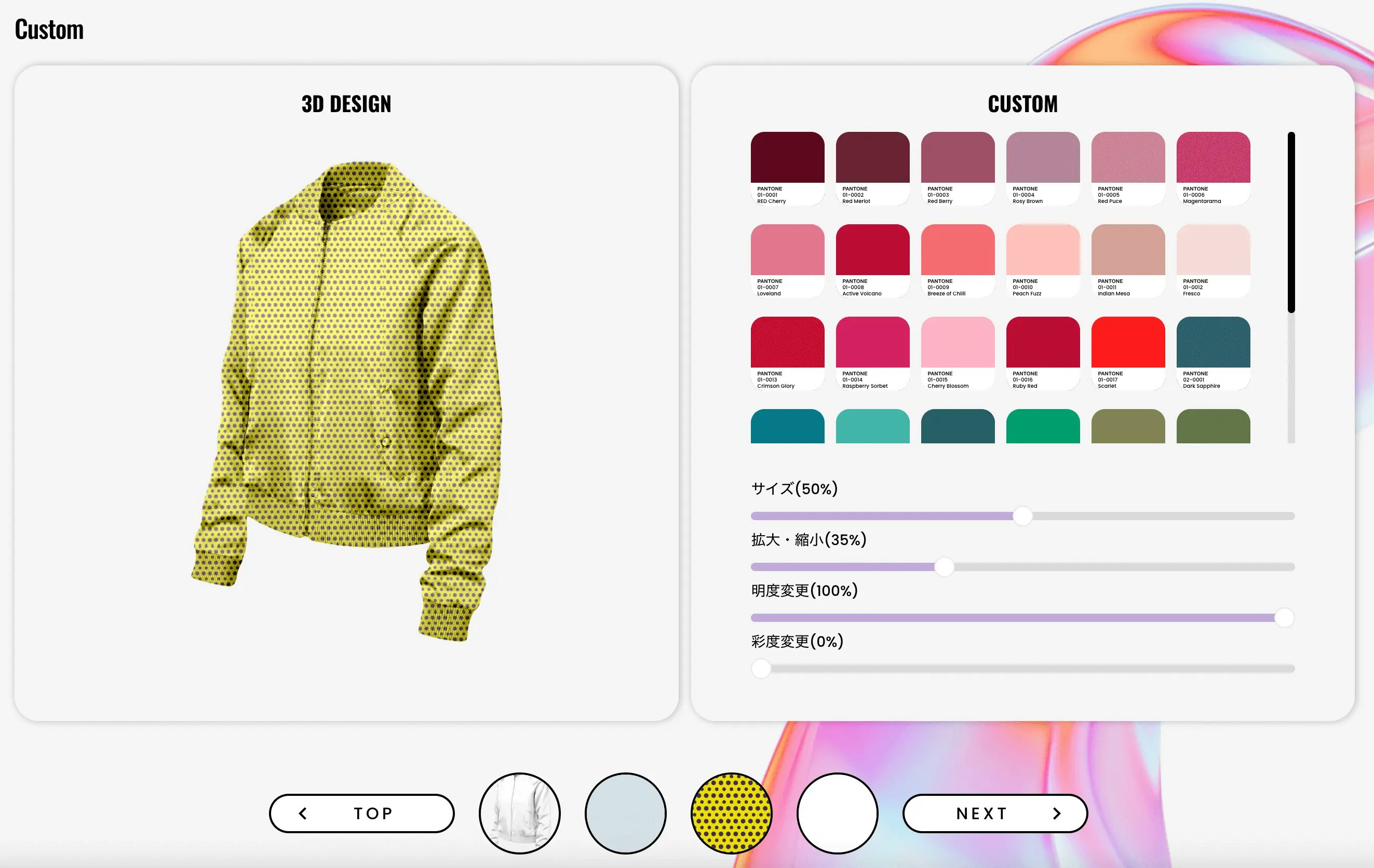

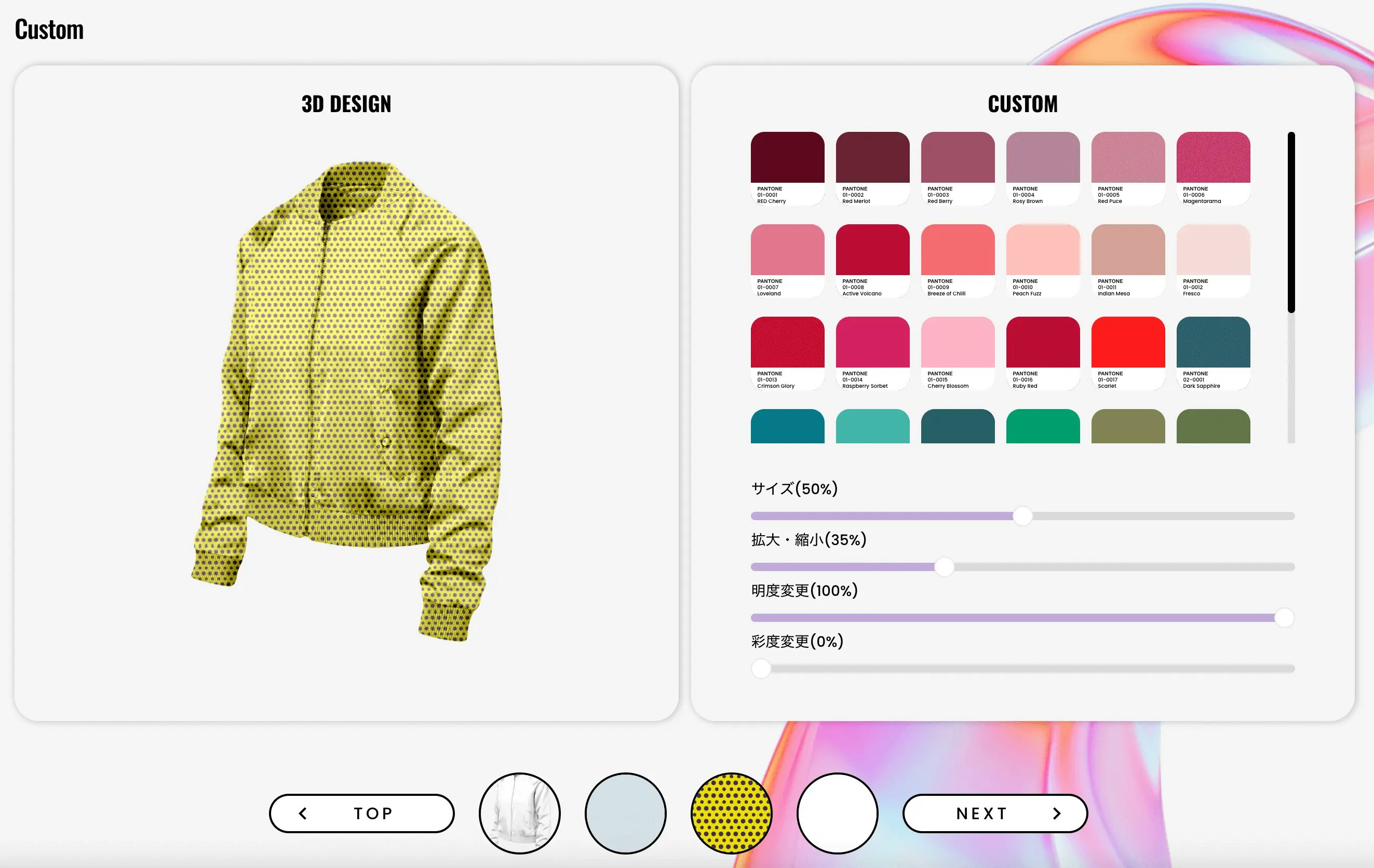

Aokumo deployed the AI Fabric Genie System, leveraging Amazon Bedrock and custom RAG-LLMs Services, to revolutionize their design workflow.

Toyoshima encountered fundamental limitations in their traditional textile design process:

Aokumo developed the AI Fabric Genie System, a cutting-edge AI-powered visualization platform tailored to Toyoshima’s textile innovation goals. Strategic AI-Driven Capabilities:

Aokumo’s AI Fabric Genie System successfully bridged the gap between Toyoshima’s traditional textile expertise and cutting-edge digital innovation. By digitizing fabric visualization and optimizing design workflows, Toyoshima achieved 50% faster design cycles, 30% market reach expansion, and breakthrough industry visibility.

This project demonstrates how artificial intelligence can revolutionize even the most established industries, driving creativity, efficiency, and new market opportunities.

Aokumo continues to help organizations redefine their industry potential by leveraging AI, generative design, and digital transformation strategies.

uid-cta-description